CreationTime:2023-07-25

With the rapid development of China's economy, the rapid increase of residents' income, the continuous expansion of housing construction area, and the continuous enhancement of people's awareness of furniture brands, China's furniture demand has great potential, and wooden furniture as a mainstream furniture product is always favored by many consumers. In 2019, China's wooden furniture production reached 315.643 million pieces, an increase of 1.4%, and the market size has risen to 662.7 billion yuan, an increase of 4%. In 2020, the total output of furniture in China was 912.21 million pieces, and the output of wooden furniture reached 321.573 million pieces, accounting for 35.3% of the total output of furniture, an increase of 1.9%, of which Guangdong Province had the highest output of wooden furniture, reaching 60.632 million pieces; Zhejiang Province followed with 42.294 million units. Therefore, it is particularly important to ensure the quality of wooden furniture products, and good quality can win a better market. The standard is the guidance of quality, high standards lead high quality, below, the secretariat on the "general technical conditions of wood furniture" GB/T 3324-2017 standard interpretation, if there is something wrong, welcome criticism and correction.

norder to promote the healthy and orderly development of the wood furniture industry, the state promulgated the "Wood furniture" (GB/T 3324-1982) as early as 1982, with the development of the wood furniture industry and the update of product technology, part of the "Wood furniture" (GB/T 3324-1982) is no longer applicable to the development of the wood furniture industry. Therefore, the state has successively issued the "General Technical Conditions for wood furniture" (GB/T 3324-1995) and "General technical conditions for Wood furniture" (GB/T 3324-2008) standards.

However, with the rapid development of science and technology and the improvement of consumers' aesthetic requirements, furniture materials are diversified, and the materials in wood furniture have been developed from the initial single wooden materials to the current composite materials that combine leather, textile fabrics and other materials. As we all know, leather and textile fabrics in order to present a variety of colors, in the processing process often add dyes for coloring or printing, so the standard needs to increase the prohibition of azo dyes requirements. In addition, government departments are increasingly concerned about the environmental performance of products, and consumer inquiries and complaints are increasingly focused on the safety and environmental performance of products, so the single limit detection of harmful substances in the "General Technical Conditions for Wood Furniture" (GB/T 3324-2008) standard is no longer applicable to the existing level of this industry.

In addition, the "General Technical Conditions for Wood Furniture" (GB/T 3324-2008) standard has increased the physical and mechanical properties of particleboard and fiberboard, including water absorption thickness expansion rate, internal bonding strength, static bending strength, screw force and other requirements. Although the wood furniture in the material put forward higher quality requirements, but these raw materials have the corresponding standards, it has been tested in the factory, and now wood furniture products are tested again, not only a waste of manpower and material resources, but also extend the detection cycle. Therefore, in order to solve some of the inapplicability of the old standard in the development process of the wood furniture industry, on October 14, 2017, the AQSIQ and the National Standardization Management Committee jointly issued the "General Technical Conditions for wood furniture" (GB/T 3324-2017) national standard.

GB/T 3324-2017 specifies the terms and definitions of wood furniture, classification, requirements, test methods, inspection rules and marks, instructions for use, packaging, transportation and storage, etc., which is applicable to wood furniture products, and other wooden pieces of furniture can be referred to.

Wood furniture refers to the main parts of the decorative pieces, accessories, other furniture made of wood, wood-based panels and other wooden materials. Wood furniture includes tables, chairs, benches, cabinets and beds and other wooden furniture, according to the main product material classification can be divided into solid wood furniture, wood-based furniture, wood-based wood furniture, wood furniture, integrated wood furniture; According to the product surface finish classification can be divided into coated furniture, wax furniture, covered furniture; It can also be classified according to the use of the product, which can be divided into wooden office furniture, wooden hotel furniture, wooden civil furniture, wooden school furniture, wooden laboratory furniture, wooden outdoor furniture and so on.

Chapter 5 of GB/T 3324-2017 is the core part of the standard, which specifies the main dimensions and deviations of wood furniture, shape and position tolerances, material requirements, appearance requirements, surface physical and chemical properties requirements, metal handle corrosion resistance requirements, mechanical properties requirements, safety requirements.

In the main dimensions, according to the product classification, the table category (desktop height, middle clearance width, clearance height), the chair category (seat height, armrest width), the cabinet category (wardrobe hanging clothes and folding clothes space depth, file cabinet net depth, net height between layers), the bed category (single bed, bunk bed length and width of the bed surface size), all the dimensions of the deviation is ±5mm.

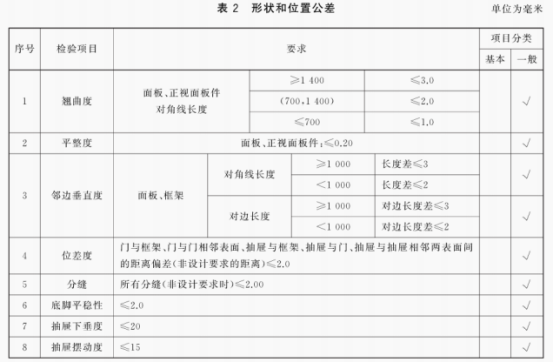

The shape and position tolerances specify the warping degree, flatness, adjacent verticality, position difference, split seam, foot smoothness, drawer sag and swing degree of wood furniture products.

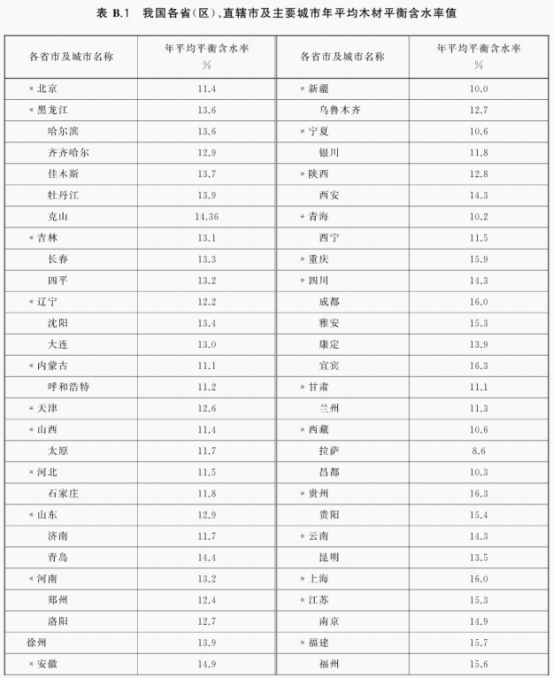

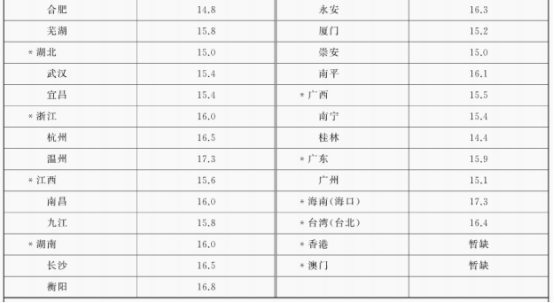

The material requirements specify the consistency of identification and things, wood moisture content, wood-based panel material requirements, of which the wood moisture content requirements are: 8% ~ (the average annual wood balance moisture content in the area where the product is located +1%). The annual average balance moisture content of wood in China's provinces, municipalities and major cities is shown in the following table.

The appearance requirements stipulate the appearance requirements of all parts involved in wood furniture products, such as wooden parts should have no cracks through, there should be no moth moth phenomenon, the appearance of wood-based panels should have no dry flowers, wet flowers, no obvious scratches, indentation, color difference, the surface of hardware plating parts without rust, burrs, dew, spraying parts without leakage, rust, corrosion, etc. The appearance requirements of glass and plastic parts are also specified. In addition, the requirements of soft package, woodworking and paint film appearance are also specified.

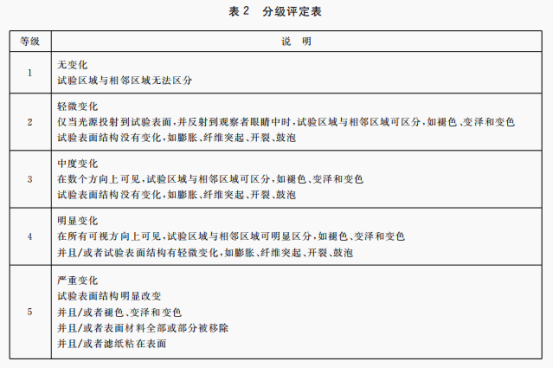

The requirements for physical and chemical properties of wood furniture surface specify the surface physical and chemical properties of paint film, soft and hard coating, raw paint coating and waxing layer. Paint film liquid resistance ≥3, moisture and heat resistance ≥3, dry heat resistance ≥3, adhesion ≥3, wear resistance ≥3, impact resistance ≥3. Soft and hard coating surface resistance to moisture and heat, dry heat resistance ≥3, pollution resistance ≥3, impact resistance ≥3, light color fastness ≥4, surface wear pattern and plain color are not exposed to the bottom phenomenon. The grading is shown in the table below.

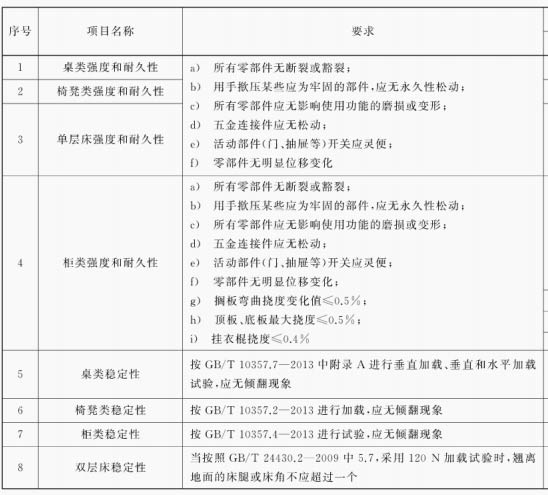

The mechanical property requirements also specify the stability, strength and durability of the table according to the classification of wood furniture products; Chairs and benches stability, strength and durability; Cabinet stability, strength and durability; Single-bed strength and durability, bunk bed stability.

GB/T 3324-2017 mainly adds a number of safety performance indicators to the safety performance requirements to ensure the safety of wood furniture during use and the standardization of the development of the wood furniture market. The safety requirements are divided into three parts: structural safety, harmful substance limit and flame retardant. Among them, the structural safety from the perspective of the design and process of wood furniture products is explicitly stipulated to avoid situations that may lead to accidents, such as "the distance between moving parts ≤5mm or ≥25mm; Folding products should be no more than the expected self-folding phenomenon "; The limit of harmful substances stipulates that the limit of harmful substances of the product complies with the provisions of GB 18584, which stipulates that the decomposition of aromatic amine dyes is prohibited in leather textile fabrics. What needs to be emphasized here is that in the context of environmental protection, the green furniture industry will be the inevitable development trend of the entire home industry.

At present, the testing of furniture on the market is generally third-party testing, third-party testing is not only efficient, but also because it has CMA qualification, the test report issued is also real and effective and has legal effect, which can help furniture manufacturing enterprises to go the last mile, and also help consumers to good quality. Never will not meet the national standards, industry standards of furniture products to the market.

Zhejiang Jiehui Testing and Certification Co., Ltd. is located in Hangzhou Xiaoshan District Hongxing Road 117, is a responsible, high quality, full service of the third party testing enterprises, the scope of enterprise testing capabilities at this stage to improve the furniture industry, including: Particleboard, joinery board, ordinary plywood, medium density fiberboard, impregnated film paper veneer board and particleboard, impregnated film paper veneer plywood and joinery board, decorative veneer veneer board, impregnated paper laminated wood floor, solid wood composite floor, antique wood floor, bamboo floor, solid wood composite floor with plywood, solid wood flooring, high density fiberboard, wood-based board and finish Test method for physical and chemical properties of wood-based panel, main dimensions of furniture table, chair and stool, main dimensions of cabinet, main dimensions of bed, physical and chemical properties of paint film on furniture surface, peeling strength of soft/hard covering surface of furniture, mechanical properties of furniture, general technical conditions of wood furniture, wooden cabinet, office furniture wooden cabinet, frame, wooden writing desk, soft furniture brown fiber elastic mattress, soft furniture Sofas, upholstered furniture spring soft mattresses, office furniture office chairs, office furniture screen tables, desks and chairs, dining tables, kitchen furniture, metal furniture general technical conditions, steel filing cabinets, coffee tables, glass furniture, children's furniture, office furniture screens, steel bookcases, reference cabinets, household cribs and folding cots, upholstered furniture, interior decoration materials Limits of hazardous substances in wood furniture, dimethyl fumarate in furniture, detection method of total volatile organic compounds in furniture, hazardous substances in plastic furniture, hazardous substances limits of solvent-based wood coatings for interior decoration materials, adhesives for interior decoration materials, hazardous substances limits for interior decoration materials carpet, carpet padding and carpet, furniture leather, textiles, leather And fur, furniture sealing strip, general soft polyether polyurethane foam, foam and rubber, furniture hardware cup dark hinge, furniture hardware

Involved industries include: furniture, flooring, whole house custom cabinets, wardrobes, bathroom cabinets, office furniture, building materials, etc. The products involved mainly include: furniture, plate, sponge, leather, paint, glue and so on. While providing relevant inspection and testing services, the company can also provide relevant professional improvement programs for the quality problems existing in the products submitted for inspection, so that the company can find out how to deal with and improve the results.

If you have testing and acceptance requirements, please contact: Duan Gong 18106515510